In industrial electrical setups — from solar power systems to water treatment plant automation — reliable electrical connections are vital. Even a small failure can disrupt critical operations.

Connectors like MC4 often go unnoticed until they fail, yet they are an industry standard in photovoltaic (PV) and industrial DC applications. For facility managers and electrical engineers, MC4 connectors play a key role in system safety, uptime, and long-term performance.

What is an MC4 Connector?

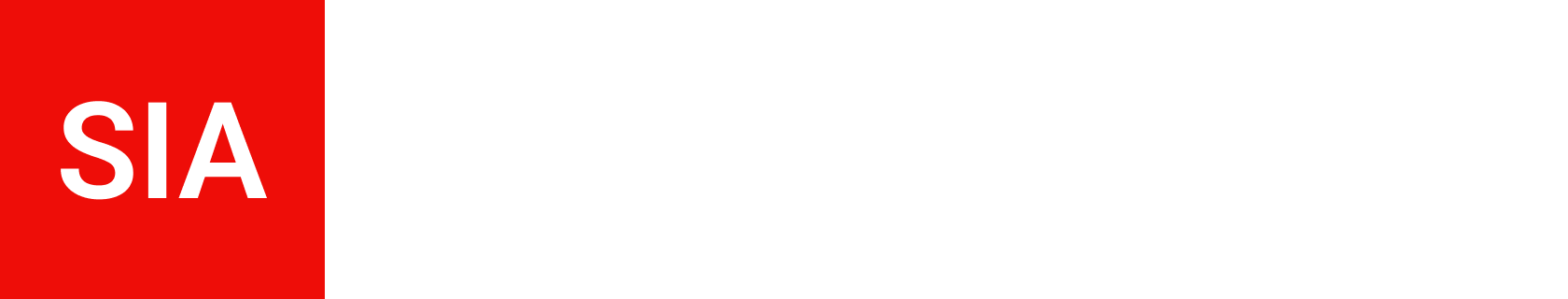

An MC4 connector (Multi-Contact, 4mm) is a single-contact electrical connector designed for DC applications, primarily in solar PV systems.

Key facts:

- Origin: “MC” stands for Multi-Contact (now Stäubli), and “4” indicates the 4 mm contact pin diameter.

- Design features:

- UV-resistant, weatherproof plastic housing (typically IP67 rated)

- Tinned copper contact pin for corrosion resistance

- Rubber sealing gland to prevent moisture ingress

- Snap-in locking mechanism (requires a special tool for disconnection)

- Performance: Typically supports up to 1000 V DC and 30 A current.

- Applications: Solar installations, battery backup systems, and industrial DC equipment.

Types of MC4 Connectors

MC4 connectors come in several variations, and choosing the right type helps maintain safety and efficiency.

Common types:

- Standard Connectors:

Male (plug) and female (socket) connectors used for positive and negative DC cables. - Branch & Y-Connectors:

Combine or split connections — ideal for solar combiner boxes and multi-inverter setups. - Advanced Versions:

- MC4-Evo2: For higher system voltages (up to 1500 V DC) and current ratings (~45 A).

- Compatible alternatives exist, but mixing brands may lead to poor fit, higher resistance, or loss of warranty.

Industrial Applications

Though widely used in solar fields, MC4 connectors power diverse industrial environments requiring reliable DC connections.

Use cases include:

- Solar PV systems: Connecting panels, combiner boxes, inverters, and batteries.

- Water treatment plants: Solar-powered monitoring, remote sensors, and battery backups.

- Automation & telecom systems: Supplying power to PLCs, sensors, RTUs, and outdoor communication devices.

Their weatherproof, vibration-resistant design ensures dependable, low-maintenance operation in harsh conditions.

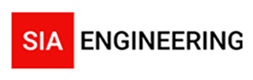

Installation Best Practices

To achieve safe and durable installations, follow proper procedures and use the right tools.

Best practices:

- Use dedicated tools: Always use an MC4 crimping tool (not generic pliers).

- Correct wire prep: Strip cable to about 7–8 mm for full copper contact.

- Crimp properly: Ensure a firm mechanical and electrical bond before final assembly.

- Lock securely: Listen for a “click” to confirm connection and sealing.

- Safety measures:

- Never connect/disconnect under load.

- Verify polarity with a DC multimeter.

- Wear PPE (gloves, safety glasses).

- Cable management:

- Provide proper strain relief and slack for thermal expansion.

- Use UV-stable ties and clear labeling.

- Protect exposed runs with conduit or shielding if necessary.

Common Issues and When to Call Experts

Even durable MC4 connectors can experience wear or damage over time.

Typical issues:

- Loose connections: Cause heating, arcing, or intermittent power loss — re-crimp or re-seat connectors.

- Moisture ingress: Leads to corrosion or discoloration — replace and reseal connectors.

- Brand incompatibility: Poor mating or locking — always match manufacturer models.

- UV degradation: Cracks or embrittlement over years — replace with UV-rated versions.

For large systems (>50 kW) or installations in hazardous environments, professional inspection and maintenance ensure compliance, warranty validity, and long-term reliability.

FAQs

1. What is an MC4 connector?

A single-contact DC connector known for weatherproofing and reliability — common in solar and industrial systems.

2. How is it different from standard connectors?

MC4 connectors are IP67-rated, support up to 1000 V DC, use tinned copper contacts, and require a special unlock tool.

3. Are MC4 connectors only for solar panels?

No. They’re also used in battery systems, industrial monitoring, and automation setups.

4. Can they be installed manually?

Yes, small systems can be installed with proper tools and training. For large setups, professional installation is safer.

5. How long do MC4 connectors last?

High-quality versions can last 20–25 years, provided regular inspections for UV, corrosion, and tightening issues are done.