National Energy Conservation Day, observed every year on December 14, promotes awareness about reducing energy consumption and improving efficiency across industries, institutions, and households. Led by the Bureau of Energy Efficiency (BEE), it encourages sustainable operations, policy adoption, and recognition through the National Energy Conservation Awards (NECA).

1. What is National Energy Conservation Day 2025?

Every year, December 14 is celebrated in India as National Energy Conservation Day to increase awareness about:

- Energy efficiency

- Renewable energy adoption

- Sustainable industrial operations

- Reduction in wastage and carbon footprint

The day highlights India’s commitment to a low-carbon, energy-secure future through technology, innovation, and responsible energy usage.

2. Who Organizes It? (BEE — Bureau of Energy Efficiency)

The event is led by the Bureau of Energy Efficiency (BEE) under the Ministry of Power.

BEE develops national programs for:

- Star rating standards

- Industrial energy audits

- Sector-wise energy efficiency guidelines

- Building codes and energy benchmarking

- National Energy Conservation Awards (NECA)

Every year, award winners are honored at Vigyan Bhawan, New Delhi.

3. Why India Needs Energy Conservation Now More Than Ever

India’s total energy demand is increasing rapidly due to:

- Industrial expansion

- Urban growth

- Increased water treatment operations

- Higher motor-based load requirements

- Rising electricity tariffs

Industries consume nearly 45 percent of India’s electricity.

Improving efficiency at industrial level is the fastest and most cost-effective way to reduce national energy demand.

4. Energy Conservation Day 2025 Theme (Expected Focus Areas)

While the official theme for 2025 is yet to be announced, current policy direction suggests a focus on:

- Mission LiFE (Lifestyle for Environment)

- Industrial decarbonization

- Smart energy systems and digital monitoring

- Updates under the Energy Conservation Act 2001

- Corporate ESG sustainability targets

These align directly with the need for advanced industrial electrical systems.

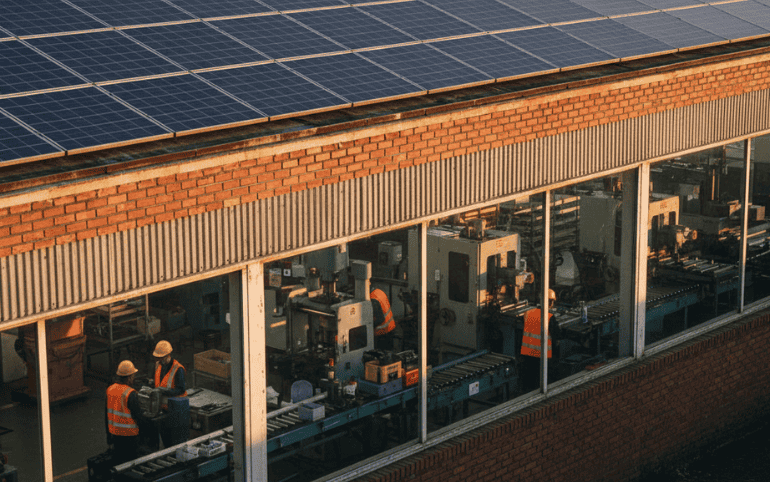

5. Why Industrial Facilities Should Care About This Day

Most industrial facilities lose 10–30 percent energy due to outdated or inefficient electrical infrastructure.

National Energy Conservation Day is an opportunity to:

- Reduce energy bills

- Improve operational reliability

- Meet energy compliance standards

- Strengthen ESG reporting

- Boost production efficiency

- Extend equipment lifespan

This is especially important for:

- Water Treatment Plants (WTP/STP/ETP/WWTP)

- Dairy and food processing facilities

- Manufacturing units

- Automotive and textile industries

- Municipal pumping systems

6. Industrial Energy Wastage: The Hidden Problem

Common energy inefficiencies found in Indian industries include:

- Low power factor (PF below 0.95)

- Motors running at full speed unnecessarily

- Lack of VFDs and controlled start cycles

- Overloaded transformers

- Manual pump operations

- Absence of SCADA monitoring

- Ageing MCC/PCC panels

National Energy Conservation Day encourages organizations to address these issues through modernization.

7. How Electrical Control Systems Support India’s Energy Conservation Goals

7.1 APFC Panels

Provide quick savings by improving PF to 0.95–0.99, reducing reactive power and avoiding penalties.

Delivers 8–12 percent energy cost reduction immediately.

7.2 MCC Panels

Improve motor efficiency, integrate VFDs, reduce downtime, and ensure balanced loads.

7.3 PCC Panels

Strengthen power distribution, reduce voltage drops, and extend electrical equipment lifespan.

7.4 PLC Automation

Enables efficient pump scheduling, motor cycle optimization, aeration control, and data logging.

Supports real-time energy monitoring and process automation.

Together, these systems help industrial facilities achieve 15–30 percent measurable savings.

8. Energy Conservation Act 2001: Compliance Requirements for 2025

The Energy Conservation Act (ECA) mandates:

- Periodic energy audits

- Maintaining PF standards

- Motor and electrical panel optimization

- Proper documentation of energy consumption

- Implementation of BEE recommendations

Non-compliance can result in:

- Penalties

- Higher operating costs

- Inspection failures

- Loss of award eligibility

Upgraded control systems automatically generate audit-ready logs such as PF history, load curves, and motor run hours.

9. National Energy Conservation Awards (NECA) and Industry Recognition

NECA highlights industries that demonstrate:

- Strong energy savings

- Advanced energy monitoring

- Implementation of efficient electrical systems

- Smart automation adoption

- Sustainability leadership

Facilities that modernize their panels, controls, and documentation stand a strong chance of being recognized for engineering excellence.

10. How Industries Can Contribute on National Energy Conservation Day

1. Measure current PF, THD, and load profiles

Identify baseline performance issues.

2. Modernize MCC, PCC, and APFC systems

Achieve immediate and sustained energy savings.

3. Automate operations using PLC and SCADA

Reduce motor and pump runtime through intelligent scheduling.

4. Conduct detailed energy audits

Reveal savings potential of 10–30 percent.

5. Train facility staff

Ensure long-term operational efficiency.

11. How SIA Engineering Supports Industrial Energy Conservation

SIA Engineering provides:

- MCC, PCC, APFC, and PLC control panel design and manufacturing

- Complete electromechanical SITC services

- Compliance-aligned electrical solutions

- SCADA integration and energy monitoring

- Water treatment, dairy, and manufacturing sector expertise

- ISO-certified engineering standards

- Fast turnaround solutions, including 3-day panel delivery in critical cases

The company’s successful deployments, such as in Gift City WTP and dairy processing facilities, demonstrate measurable improvements in energy efficiency.

12. Awareness Combined with Action

National Energy Conservation Day is not just about spreading awareness.

It is a reminder for industries to adopt smarter infrastructure, modernize their control systems, and actively participate in India’s energy-saving mission.

Every optimized electrical panel accelerates India’s progress toward a more sustainable industrial future.

Call to Action

To improve your facility’s energy performance and reduce costs by 15–30 percent, request an industrial energy efficiency consultation with SIA Engineering.Email: support@siaengineering.in

Phone: +91-8800311413