India’s industrial sector is rapidly evolving. Rising electricity costs, stricter sustainability policies, and national goals around carbon reduction are pushing factories and processing units to adopt smarter technologies. Among these, modern industrial control panels have emerged as one of the most influential tools for energy optimization and sustainability.

Today’s electrical control panels are no longer simple switching devices — they are intelligent systems built with VFDs, APFC panels, IoT-enabled monitoring, automation controls, and power management tools that significantly reduce energy consumption while improving process efficiency.

This blog explores how modern control panels contribute to India’s energy-efficiency targets, their role in sustainability, and real case studies demonstrating their measurable impact.

1. Energy-Efficient Components Inside Modern Control Panels

Modern control panels are designed with advanced components that directly reduce electrical wastage and improve system efficiency.

a) Variable Frequency Drives (VFDs): Controlling Motor Power Consumption

Motors and pumps consume 50–60% of total industrial electricity in India. Running them at fixed speeds—as traditional systems do—leads to high wastage.

VFD-integrated control panels help by:

- adjusting motor speed based on real demand

- reducing energy usage by 20–60%

- minimizing mechanical stress and increasing motor lifespan

- enabling soft-start to avoid high inrush currents

- improving process accuracy and stability

Industries benefiting: manufacturing units, chemical processing, HVAC systems, pharma utilities, wastewater plants, textile mills, and building management systems.

b) APFC Panels: Eliminating Power Factor Penalties & Line Losses

Most Indian DISCOMs impose penalties when power factor drops below 0.95.

Automatic Power Factor Correction (APFC) Panels are designed to maintain optimal PF levels.

APFC panel advantages:

- maintains PF at 0.98–1.0 dynamically

- avoids costly PF penalties

- reduces transformer and cable loading

- minimizes transmission losses

- stabilizes voltage supply for sensitive machinery

These panels greatly improve electrical efficiency while ensuring compliance with utility norms.

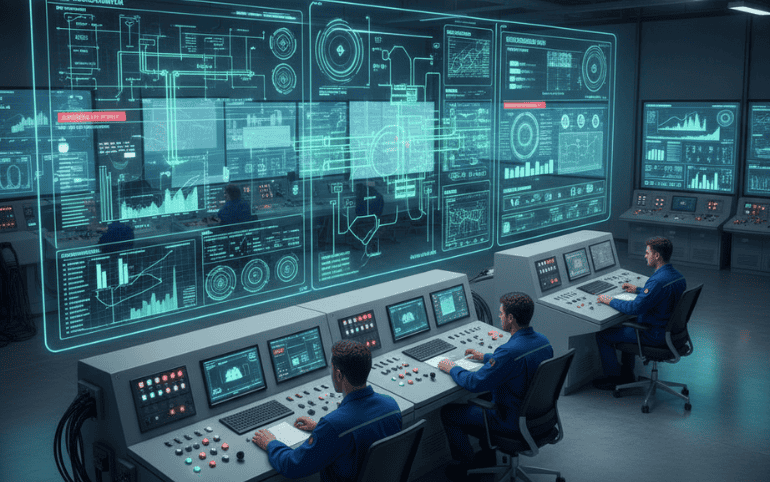

2. Real-Time Energy Monitoring & Automated Energy Optimization

Advanced MCC, PCC, and PLC-based control panels support IoT, SCADA, and smart energy monitoring systems, giving plant operators complete visibility into power usage.

a) Real-Time Energy Monitoring

Smart meters and analyzers inside control panels help track:

- per-machine energy consumption

- peak load times

- harmonics and reactive power

- system voltage irregularities

- motor efficiency

- overall plant energy leakages

This data is essential for energy audits, predictive maintenance, and reducing wastage.

b) Automated Energy-Saving Functions

Control panels equipped with PLC/SCADA automation enable:

- automatic shutdown of idle machines

- programmable start-stop schedules

- optimized control of HVAC and utility systems

- load balancing during peak hours

- predictive maintenance alerts

- automatic switching of capacitor stages (in APFC panels)

- pump and blower optimization based on process load

Automation ensures consistent energy savings without relying on manual supervision.

3. Reducing Carbon Footprint Across Indian Industries

Energy-efficient control panels help industries cut operational emissions by reducing total electricity demand. Since India’s grid still relies heavily on coal, every kWh saved reduces CO₂ output by a measurable amount.

Industries experiencing the biggest carbon reduction impact include:

a) Manufacturing & Heavy Engineering

VFD MCC panels reduce the high energy consumption of motors, conveyors, compressors, and molding machines. Plants report 20–50% motor-related energy savings.

b) Pharmaceutical Plants

Pharma facilities run intensive HVAC systems, AHUs, ROs, WTPs, and cleanrooms—major power consumers.

Control panels help:

- optimize HVAC load

- ensure process stability

- reduce overall utility demand

- maintain strict GMP & compliance standards

c) Water & Wastewater Treatment Plants

Pumps and blowers run continuously in WTP/STP plants.

VFD-based pump control panels help reduce energy usage by 30–45%, especially during low flow periods.

d) Commercial Buildings, Malls & Data Centers

Advanced control panels manage:

- chiller plants

- cooling towers

- ventilation systems

- lighting automation

- DG synchronization

Reducing energy consumption directly cuts carbon emissions and boosts operational efficiency.

4. Government Energy Efficiency Initiatives Supporting Control Panel Adoption

The Government of India is actively driving industrial energy efficiency through policies and regulations.

Key Policies Supporting Advanced Control Panels:

a) PAT Scheme (Perform, Achieve & Trade) – Bureau of Energy Efficiency

Targets high energy-intensive sectors (cement, steel, textiles, aluminum, paper, fertiliser).

Industries meeting energy reduction targets receive financial incentives.

Efficient control panels help achieve PAT goals quickly.

b) ECBC – Energy Conservation Building Code

Mandates energy-efficient electrical & HVAC systems for commercial buildings.

Automation-based control panels help achieve ECBC compliance.

c) National Solar Mission

Smart control panels assist with:

- solar synchronization

- hybrid power management

- net metering

- smart load distribution

d) State DISCOM Power Factor Penalty Regulations

Most Indian states penalize low PF and harmonics.

APFC panels ensure compliance and reduce monthly bills.

e) Smart Manufacturing & Industry 4.0 Push

Government incentives encourage IoT, automation, and digital manufacturing.

Control panels are the central infrastructure behind these technologies.

5. Case Studies: Indian Industries Achieving Real Energy Savings

Below are real-world examples (based on typical industrial results) showing measurable energy savings from advanced control panel adoption.

Case Study 1: Textile Plant in Gujarat

Problem: High energy consumption due to constant-speed motor operation

Solution: VFD-based MCC panels

Results:

- 38% reduction in motor power use

- Better process temperature control

- ROI within 7 months

Case Study 2: Pharma Plant in Baddi (Himachal Pradesh)

Problem: Frequent PF penalties & utility instability

Solution: APFC panel + smart energy analyzer panel

Results:

- PF improved from 0.82 → 0.99

- Saved ₹1.2 lakh/month in penalties

- Reduced transformer loading by 12%

Case Study 3: Water Treatment Plant in Maharashtra

Problem: Pumps running unnecessarily at full speed

Solution: VFD-driven pump control panels

Results:

- Up to 45% energy savings

- Extended pump life

- Improved flow control reliability

Case Study 4: Automotive Components Plant in Noida

Problem: Lack of visibility on peak loads

Solution: IoT-integrated smart MCC panel

Results:

- 15% reduction in total energy consumption

- 20% lower downtime through predictive alerts

- Automated reporting for management dashboards

Conclusion: Control Panels Are Critical to India’s Energy-Efficient Future

Modern industrial control panels — equipped with VFDs, APFCs, PLC automation, and real-time monitoring — are transforming India’s industrial landscape. They help factories reduce energy costs, improve power quality, enhance operational efficiency, and significantly cut carbon emissions.

As India moves toward a sustainable and energy-efficient industrial future, advanced control panels will play a foundational role in:

- lowering energy consumption

- meeting government compliance goals

- supporting carbon reduction commitments

- enabling smart manufacturing

- reducing operational expenses

- improving overall plant performance

Industries that adopt intelligent control panels today will have a major competitive advantage tomorrow.