Industrial facilities rely on Motor Control Centers (MCCs) to distribute power to motors safely and consistently. But as plants scale, traditional MCCs can become wiring-heavy and slower to troubleshoot, especially when maintenance teams need quick answers about trips, overloads, and recurring motor issues. That’s where the Intelligent MCC Panel (often called an Intelligent Motor Control Center or IMCC) becomes a major upgrade—because it turns each motor feeder into a data-rich, network-connected asset instead of a “black box.”

What is an Intelligent MCC (IMCC)?

An Intelligent MCC (IMCC) is an MCC where feeders provide digital operating data and diagnostics to a PLC/SCADA system using industrial communication, reducing extensive hardwiring and improving reliability and troubleshooting speed. In practical terms, an IMCC keeps the core MCC purpose the same—motor power distribution and control—but adds smart motor management hardware that enables real-time visibility and remote diagnostics.

Traditional MCC vs Intelligent MCC (key difference)

In a conventional MCC, each feeder includes components like circuit breakers, contactors, current transformers (CTs), relays, and control devices that manage power from the busbar to the motor. When the MCC has many feeders, the control wiring from individual feeders to PLC panels increases significantly, which can increase complexity and reduce efficiency and reliability.

In an IMCC, feeders are largely the same as a normal MCC feeder, but the architecture changes by adding a motor management/communication device at the feeder level (a widely used example in industry is Siemens SIMOCODE). Instead of sending many separate hardwired signals to the PLC, local feedback/control wiring terminates at this device, and the device sends data to the PLC over a common protocol like Profibus or Profinet—dramatically reducing external wiring and simplifying integration.

What “intelligence” really means inside the panel

Intelligence in an MCC panel is not just “a screen” or “a smart meter”—it’s the ability to read and write meaningful feeder and motor data through communication addresses rather than dozens of individual I/O points. The IMCC concept supports exchanging a wide variety of data and commands, such as motor start/stop, feeder healthy, motor run, motor trip, emergency stop status, local/remote selection status, power failure feedback, stalled rotor feedback, and unbalance trip feedback.

This matters because maintenance teams don’t only need to know “motor stopped”—they need to know why it stopped, what conditions led up to it, and what to check first. When diagnostics are digitized at the feeder level, troubleshooting time can be reduced substantially compared to tracing hardwired signals across panels and terminals.

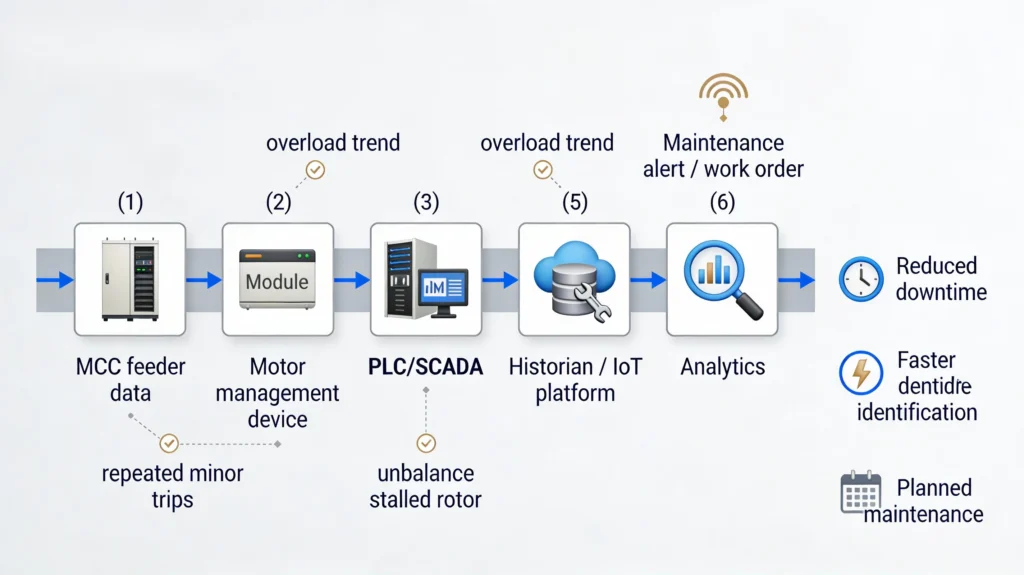

Where IoT fits: turning MCC data into predictive maintenance

Once your MCC is capable of producing structured electrical and status data (instead of only basic lamps and trips), it becomes much easier to connect that data to modern monitoring stacks—SCADA historians, dashboards, and IoT platforms. That connectivity is the bridge from “connected MCC” to predictive maintenance, where maintenance is triggered by equipment condition and early warning indicators rather than only schedules or breakdown events.

Examples of predictive-maintenance signals from intelligent MCCs

- Repeated minor trips or abnormal patterns in feeder status can indicate developing issues before a major failure occurs.

- Motor protection and management functions (configured with motor parameters like current/power) allow smarter trip behavior and earlier fault identification.

- With fewer wiring points and richer diagnostics, recurring faults can be identified faster and corrected with less downtime.

If you want to connect this topic with existing SIA content, internally link the phrase Predictive Maintenance to your solar predictive maintenance blog (it builds the same “continuous monitoring + early fixes” concept for another asset class).

Practical benefits for industrial power distribution

An intelligent MCC improves power distribution operations mainly by improving visibility, reducing wiring complexity, and enabling better decision-making. It reduces the amount of external hardwiring to PLC panels by shifting feeder data exchange to a networked communication link (e.g., Profibus/Profinet) which lowers complexity and speeds commissioning.

Operationally, IMCC data helps teams move from reactive firefighting to structured maintenance planning, because faults and statuses are captured with more context at the feeder level. This is especially valuable in motor-heavy industries where even a short unplanned stop can disrupt production lines, utilities, pumping systems, or material handling.

Implementation checklist (engineer-friendly)

Use this checklist to keep the project practical and “site-ready”:

- Identify which motors/feeders are critical and start intelligence there (rather than trying to convert everything at once).

- Select a feeder-level motor management/communication approach (e.g., SIMOCODE-type devices or equivalent) that can transport the required data set.

- Align communication choice to your automation ecosystem (Profibus/Profinet are common examples used for IMCC communication to PLC).

- Define what your maintenance team will actually use: alarms, dashboards, trip reasons, and escalation workflows, not just raw data points.

For internal linking that matches your existing positioning, you can also link Smart automation to your “Future of Industrial Engineering in India 2025” blog and Smart control panels to your smart solar control panels blog (the reader intent overlaps strongly: automation + monitoring + ROI).

FAQ’S

1. What is an Intelligent MCC (IMCC) panel?

An IMCC is an MCC that communicates feeder electrical/diagnostic data to PLC/SCADA over protocols like Profibus/Profinet.

2. How is IMCC different from a normal MCC?

The feeder is similar, but IMCC adds a motor management device (e.g., Siemens SIMOCODE) to share data digitally and reduce hardwiring.

3. How does an IMCC enable predictive maintenance?

It provides continuous operating/trip diagnostics so teams can detect patterns early and plan maintenance before breakdowns.

4. Which protocols are used in intelligent MCCs?

Common options include PROFIBUS and PROFINET, and many platforms also support Modbus RTU/EtherNet/IP.

5. What is the biggest benefit of IMCC for maintenance teams?

Reduced wiring complexity and faster troubleshooting because feeder diagnostics are available digitally.